TYRES

TYRES

The tyre is the ONLY element to make contact between the vehicle and the road. That is why using and maintaining tyres correctly, as well as being aware of their characteristics, is fundamental in order to guarantee safety in any situation, to increase your tyres’ lifespan and to save money. Always remember to drive safely and respect the environment.

If you drive with tyres with a tread-depth of less than 1.6 mm, you could face a fine.

TYRE ADVICE

SIDEWALL MARKINGS

TYRE PRESSURES

TYRE TREAD DEPTH

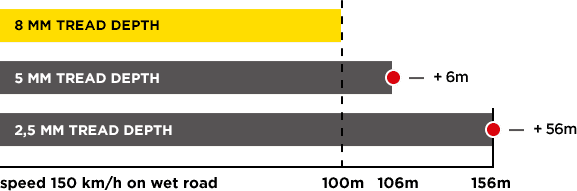

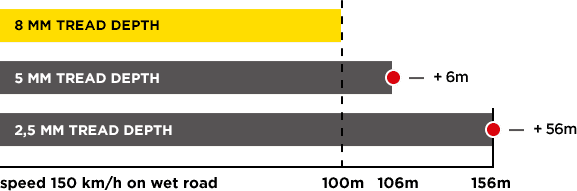

BRAKING DISTANCE

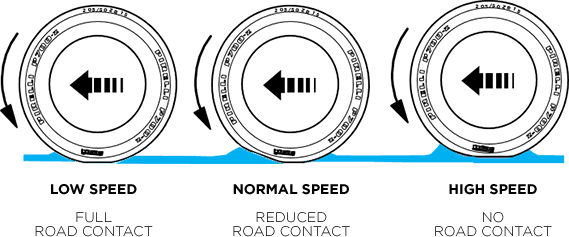

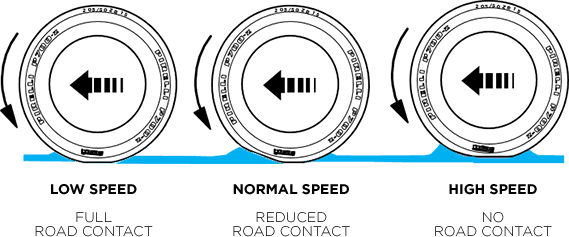

HYDROPLANING

THE EU TYRE LABEL

THE DETAIL

THE TYRE SPECIALISTS

THE TYRE SPECIALISTS

PUNCTURE REPAIRS

Tyre repairs are covered by a British Standard - BSAU159f:1990 - which splits repairs into two categories - minor repairs and major repairs. The British Standard also defines limits to the location, size and number of repairs that can be carried out and makes recommendations also on the repair materials to be used.

A tyre must always be checked thoroughly before it is repaired. If the tyre displays any of the following, it should not be repaired;

Illegal tread depth (below 1.6mm across the central ¾ of the tyre tread throughout the entire circumference)

Run flat damage - breakdown of the tyre's structural integrity

Secondary damage - caused by the injuring object

Ageing/deterioration of tyre rubber

Bead damage

Exposed cords

Faulty/poor previous repairs

Inspection is vital. If there are any doubts as to whether a tyre should be repaired or not we do not repair it.

The repairable area is defined as a percentage of the tyre's “nominal” section width and thus varies by the size of the tyre. The repairable area is based on the centre line, eg. 82mm means 41mm on either side of the centre line of the tyre.

Repairing Run Flat tyres

Runflat tyres have been specifically designed to withstand exceeded loading even when driven with little or no tyre pressure. As we are unable to accurately test the integrity of a run flat tyres structure after run flat use, for safety reasons we do not and do not reccomend puncture repairs to be carried out on run flat tyres.

PUNCTURE REPAIRS

PRICE MATCH

CONTACT

OPENING HOURS

- Mon - Fri

- -

- Sat - Sun

- Closed

CONTACT

BTE Automotive Ltd

Unit 34 & 44 Woolmer Trading Estate

Bordon

Hampshire

GU359QF

t. 01420477655

OPENING HOURS

- Mon - Fri

- -

- Sat - Sun

- Closed